Rockwell Automation is dedicated to creating solutions that monitor and eliminate downtime caused by nuisance trips and dirty power. Through the use of patented technologies, Rockwell Automation delivers clean power to the manufacturing floor and enables customers to maximise their productivity with no batteries, no moving parts and no expensive software packages.

Allen-Bradley Dynamic Sag Correctors (DySC) from Rockwell Automation are unique and exclusive industrial power quality solutions that protect against voltage sags and momentary outrages that account for a significant amounts of manufacturing downtime and damaged equipment. They do the job with no batteries, no moving parts and virtually no maintenence, making them ideal for critical manufacturing processes and sensitive electronics that require sag ride-through protection for up to 5 seconds. And the DySC is so efficient that it virtually pays for itself in energy savings alone, when compared to other power quality technologies. If you want to maximise facility uptime, you’ll want to look at DySC solutions.

-

DySC Theory of Operation

DySC make use of high speed IGBT inverter to pull extra power from utility source to provide the voltage sag correction. For events when there is a short interruption, it pulls a small amount of energy from the capacitor to provide for this short duration of interruption.

Normal Voltage Condition

DySC static switch is closed and passes the utility voltage directly to the load.

Voltage Sag Condition

When a sag event occurs, the DySC controller opens the static switch, thereby inserting the PWM inverter in the series with the utility and the load, typically in less than 2ms. When the sag event ends, the converter is turned off and the static switch is closed, thereby connecting the utility directly to the load again.

-

Superior Product Features in Voltage Sag Mitigation

The 5 NOs of Benefits of DySC

No High Energy Cost

DySC has high operating efficiency with up to 99% efficient. The ultra-low heat loss makes the DySC as one of the system with lowest energy consumption. The chart below shows a staggering difference in energy cost when comparing a 1MVA DySC with conventional system.

No Expensive Service Contract or Software

DySC users do not need to sign mandatory servicing contracts or buying complex and expensive software. DySC is design to have minimum maintenance which the users can carry out simple maintenance work. For example, replacing external air filters can be easily carried out by the users periodically without having to activate Rockwell Automation.

No Environment Impact

Vibration, loud noise, high heat or gas emission is non existent with DySC. Its quiet operation produces negligible environment impact in the area where it is installed. This helped reduce auxiliary system or site preparation for DySC installation, such as air conditioning system, special floor preparation and gas venting system.

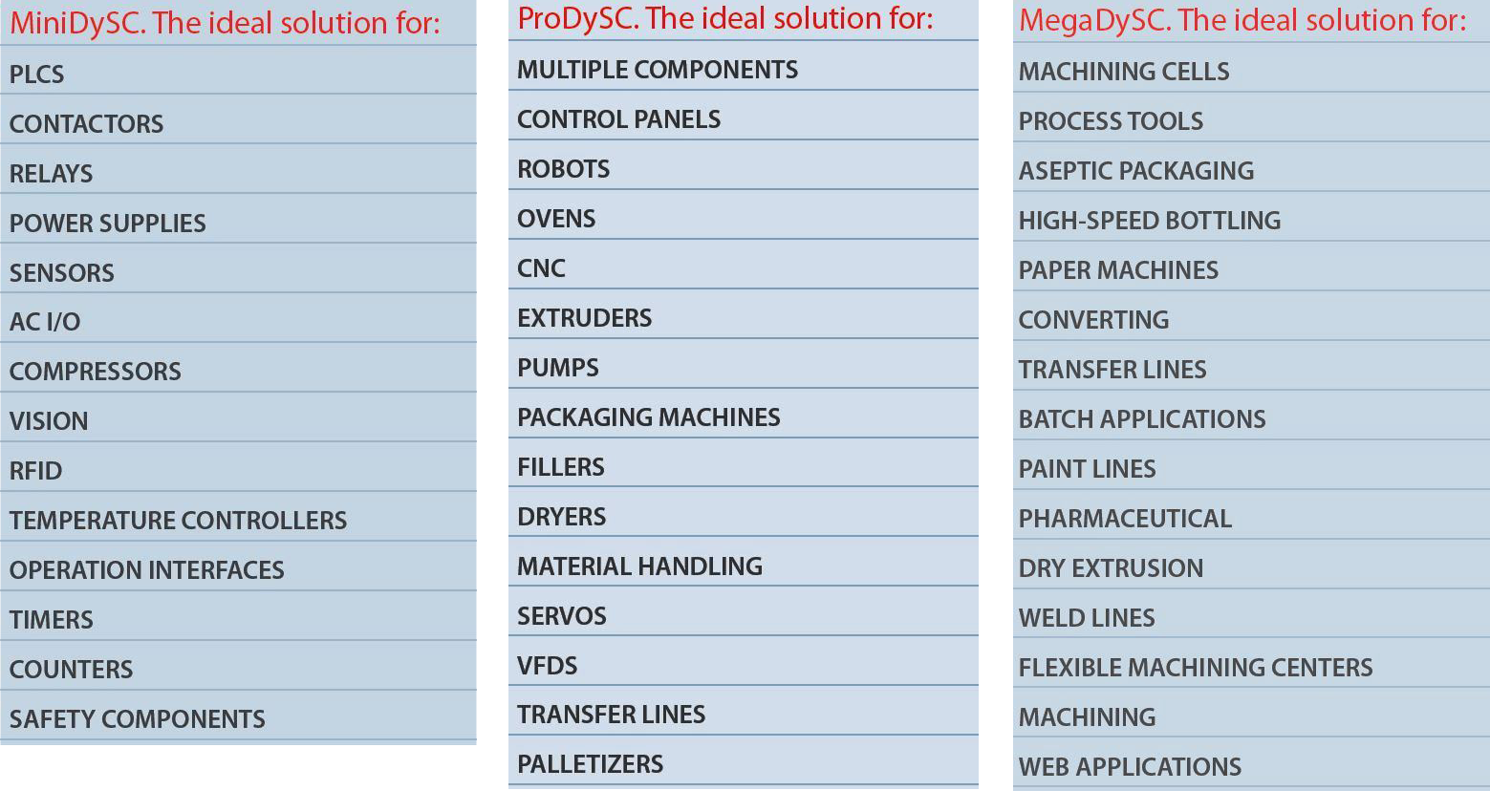

No Risk

DySC has been widely used in many industry applications which include the Semiconductor, Automotive, Food and Chemical Industries. More than 1000 units have been installed and proven to help save voltage sag events. Almost all of the DySC installed are standard products that are tried and tested by many Fortune 500 companies.

Other Benefits of DySC

Extremely Scalable

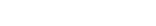

From 0.5kVA to 2000kVA – No matter the size, scope or focus of your industry, we can configure a DySC to fit any application. From Machine to facility-wide protection; single and three phase powered equipment.

100% Sag Protection

Your lines receive an unbroken flow of clean power, keeping operations running smoothly, maximising MTBF (mean time between failure), reducing MTTRTTR (mean time to repair) and maintaining your efficiency and bottom line.

Features :

Relatively Compact Size

Highest Overall Efficiency (>99%)

Exceed SEMI F47 Compliant

Application Example for DySC Protection: –

DySC Protects from Component – , Machine – , to Process – Level : –